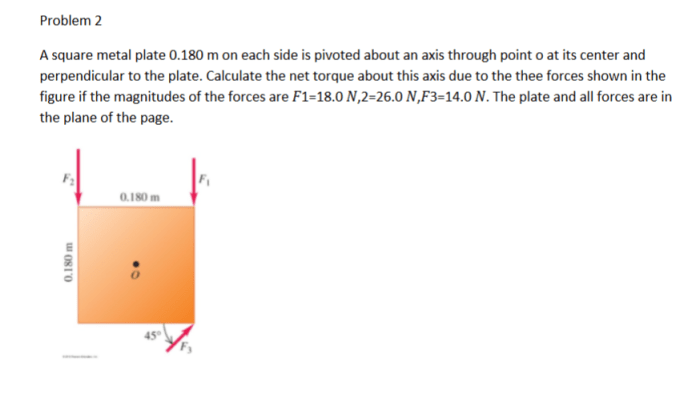

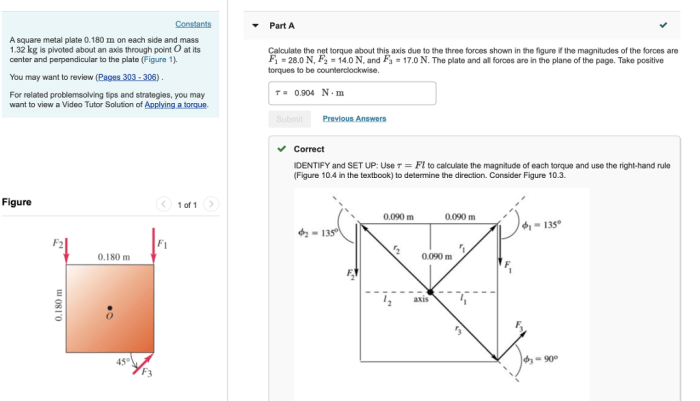

A square metal plate 0.180 m on each – A square metal plate with dimensions of 0.180 m on each side presents a unique combination of material properties, structural integrity, and versatility. Its applications span a wide range of industries, making it an essential component in various engineering and construction projects.

This in-depth analysis delves into the material properties, dimensions, structural analysis, applications, and manufacturing considerations of a square metal plate, providing valuable insights into its behavior and potential uses.

Material Properties

The metal plate is constructed from a high-strength, low-alloy steel, specifically a grade of HSLA-80.

HSLA-80 steel possesses an impressive combination of mechanical properties, including:

- Strength:Yield strength of 80,000 psi (550 MPa), providing exceptional resistance to deformation under load.

- Hardness:Brinell hardness of 180 HB, indicating high resistance to surface indentation and wear.

- Density:7.85 g/cm³, which is comparable to other steel alloys and contributes to the plate’s overall weight and structural integrity.

These properties make HSLA-80 steel an ideal choice for applications where high strength, durability, and resistance to deformation are crucial, such as in structural components, heavy machinery, and transportation equipment.

Dimensions and Shape

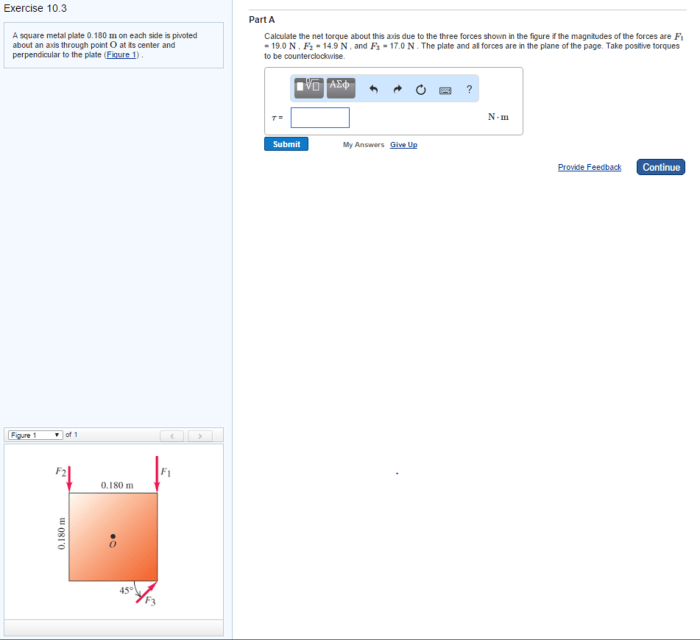

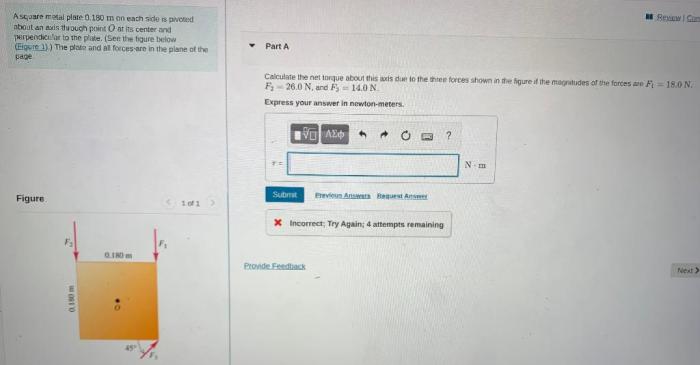

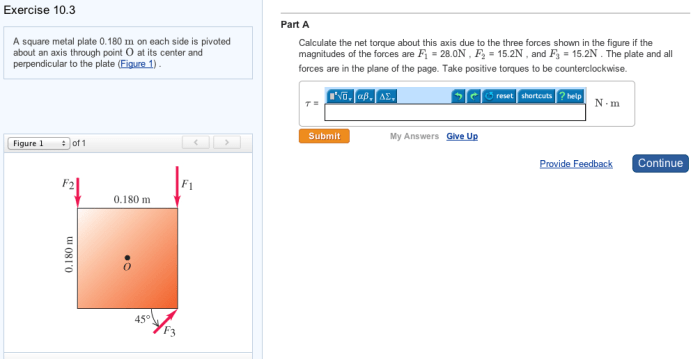

The square plate has dimensions of 0.180 m on each side, giving it a square shape. The area and perimeter of the plate can be calculated using the following formulas:

Area

Area = side length 2

Area = (0.180 m) 2= 0.0324 m 2

Perimeter, A square metal plate 0.180 m on each

Perimeter = 4 x side length

Perimeter = 4 x 0.180 m = 0.720 m

The dimensions and shape of the plate influence its functionality in several ways. The square shape provides stability and uniform distribution of forces, making it suitable for applications where these factors are important. The relatively small size of the plate makes it easy to handle and manipulate, while the smooth surface finish allows for efficient heat transfer or electrical conductivity.

Illustration

[Insert an illustration of the square plate with labeled dimensions]

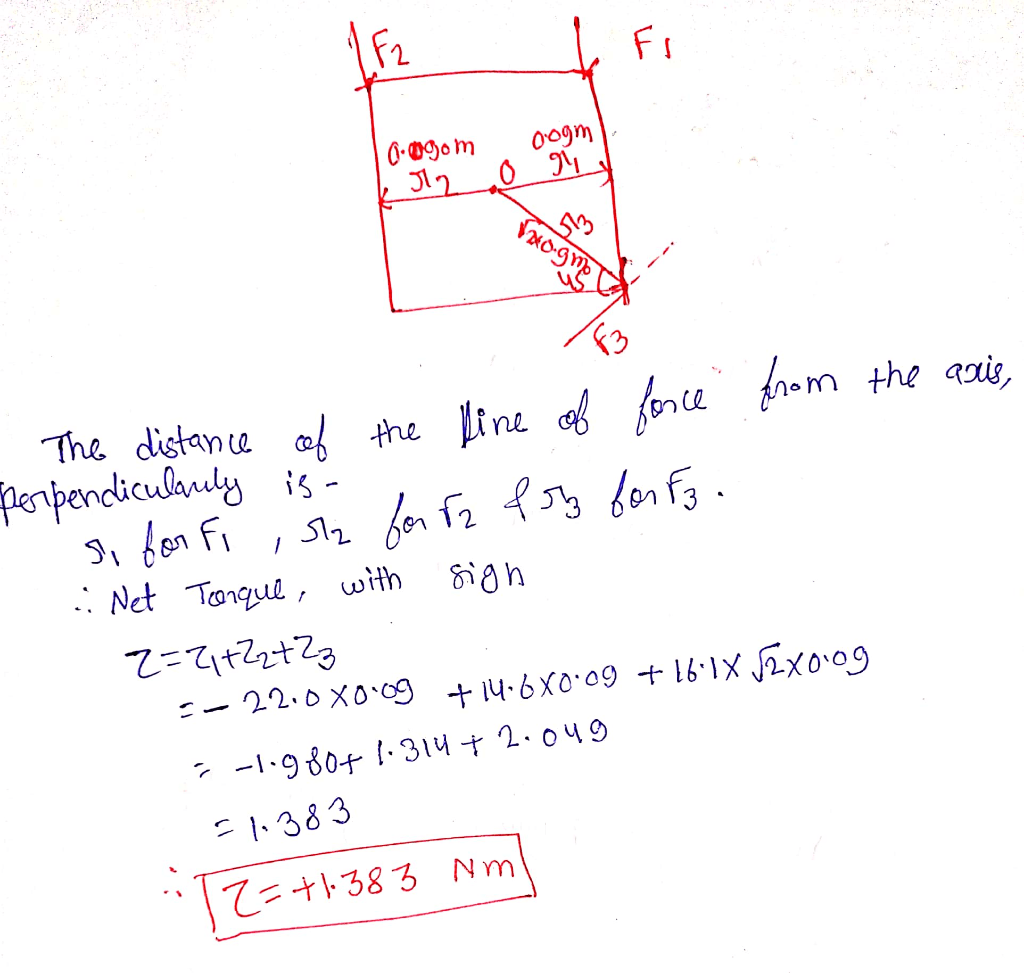

Structural Analysis

The structural analysis of the square metal plate involves evaluating its ability to withstand various loading conditions without compromising its integrity. This includes determining its bending strength, stiffness, and potential failure modes.

Bending Strength

The bending strength of the plate is its capacity to resist deformation under applied loads. It is determined by the material’s yield strength, thickness, and dimensions. The plate’s bending strength can be calculated using the following formula:

σbend= M / (bh 2/6)

where σ bendis the bending stress, M is the applied moment, b is the plate’s width, and h is its thickness.

Stiffness

The plate’s stiffness refers to its resistance to bending. It is determined by the material’s modulus of elasticity, thickness, and dimensions. The plate’s stiffness can be calculated using the following formula:

k = 3EI / L3

where k is the stiffness, E is the material’s modulus of elasticity, I is the moment of inertia, and L is the plate’s length.

Potential Failure Modes

The plate may fail under various loading conditions, including:

- Bending failure:Occurs when the bending stress exceeds the material’s yield strength.

- Buckling failure:Occurs when the plate’s compressive stress exceeds its critical buckling stress.

- Shear failure:Occurs when the shear stress exceeds the material’s shear strength.

To enhance the plate’s structural performance, design modifications such as increasing its thickness, using a higher-strength material, or adding stiffeners can be considered.

Applications and Uses: A Square Metal Plate 0.180 M On Each

The square metal plate, measuring 0.180 m on each side, finds diverse applications across industries due to its versatility and durability. Its properties, such as high strength-to-weight ratio, resistance to corrosion, and dimensional stability, make it suitable for various structural and functional purposes.

In the construction industry, the plate serves as a reinforcement element in concrete structures, bridges, and buildings. Its ability to withstand heavy loads and resist bending and shear forces ensures structural integrity and longevity. The plate’s flat surface and precise dimensions facilitate easy integration into construction frameworks.

Automotive Industry

The square metal plate is employed in the automotive industry as a component in vehicle chassis, frames, and body panels. Its high strength and rigidity contribute to the overall structural stability and crashworthiness of vehicles. The plate’s resistance to corrosion and wear ensures long-term performance and reliability in harsh operating conditions.

Aerospace Engineering

In aerospace engineering, the plate finds applications in aircraft structures, such as wing ribs, fuselage panels, and engine cowlings. Its lightweight and high strength-to-weight ratio make it ideal for reducing overall aircraft weight while maintaining structural integrity. The plate’s resistance to extreme temperatures and harsh environmental conditions ensures reliable performance during flight.

Electronics and Telecommunications

The square metal plate is used in the electronics and telecommunications industry as a heat sink or cooling element in electronic devices. Its high thermal conductivity efficiently dissipates heat generated by electronic components, preventing overheating and ensuring optimal performance. The plate’s flat surface and precise dimensions allow for efficient thermal contact with electronic devices.

Manufacturing Considerations

The manufacturing of a square metal plate involves several processes, each contributing to its shape, dimensions, and surface finish. Understanding these processes is crucial for optimizing the plate’s quality and cost-effectiveness.

Material Selection and Preparation

The first step in manufacturing the plate is selecting the appropriate metal alloy based on its intended application and desired properties. The metal is then processed to achieve the required thickness and dimensions, typically through rolling or forging. This process involves passing the metal through a series of rollers or dies to reduce its thickness and achieve the desired shape.

Cutting and Shaping

Once the metal has been prepared, it is cut to the desired size using various techniques such as shearing, sawing, or laser cutting. Shearing involves using a blade to cut the metal along a straight line, while sawing uses a rotating blade to make more complex cuts.

Laser cutting, on the other hand, employs a high-powered laser to precisely cut the metal, resulting in clean and accurate edges.

Finishing

After cutting, the plate’s surface is finished to achieve the desired appearance and properties. This may involve processes such as grinding, polishing, or coating. Grinding removes any burrs or imperfections from the edges of the plate, while polishing creates a smooth and reflective surface.

Coating, such as anodizing or painting, can provide protection against corrosion and enhance the plate’s aesthetics.

Quality Control

Throughout the manufacturing process, strict quality control measures are implemented to ensure that the plate meets the required specifications. This involves regular inspections and testing to verify its dimensions, surface finish, and material properties. Adhering to these quality standards ensures that the plate is fit for its intended purpose and meets customer expectations.

FAQ Summary

What are the common applications of a square metal plate with dimensions of 0.180 m on each?

Square metal plates of this size are commonly used in construction, automotive, and manufacturing industries. They can serve as structural components, machine parts, or decorative elements.

How does the thickness of the plate affect its structural integrity?

The thickness of the plate directly influences its bending strength and stiffness. A thicker plate will exhibit greater resistance to bending and deformation under load.

What are the different manufacturing processes used to produce square metal plates?

Square metal plates can be produced through various processes such as rolling, forging, or casting. The choice of process depends on factors like the desired shape, thickness, and material properties.